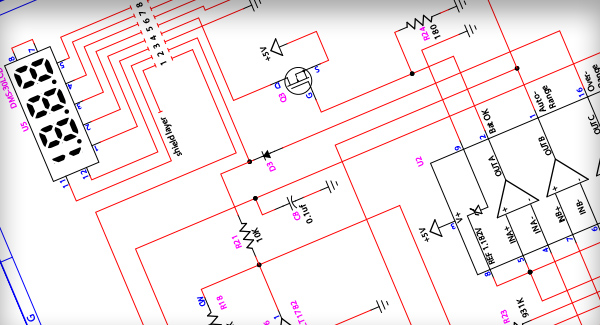

Our PCB Manufacturing Services

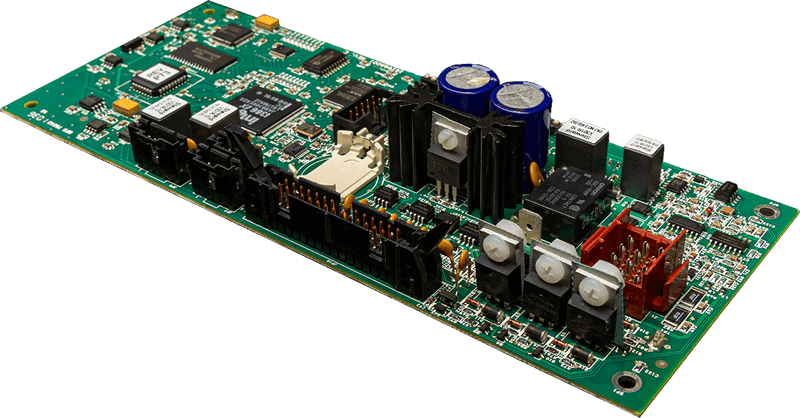

Our affordable, professional PCB manufacturing services provide you with quality printed circuit boards built to your specifications, quickly and on time.

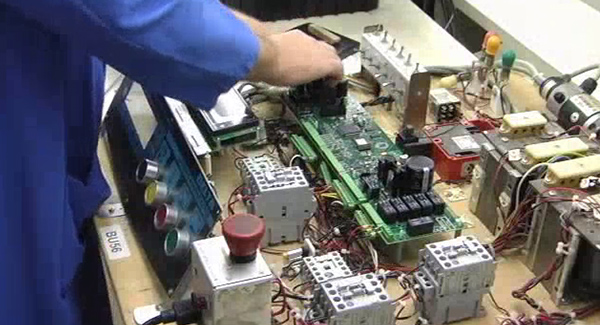

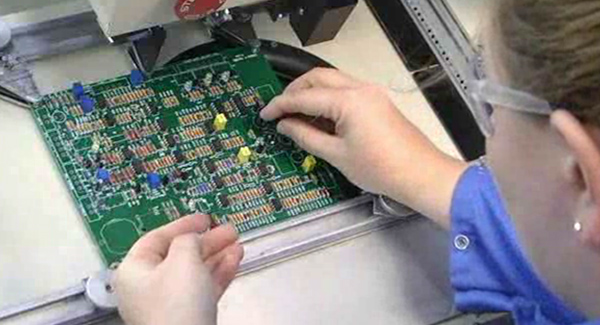

GIC’s precision assembly capabilities include:

- turnkey PCB

- cable

- harness

- box build assembly

- surface mount design and through-hole technology

- automated optical inspection (AOI, both 2D and 3D)

- X-Ray

- wave solder

- conformal coating

- encapsulation (potting)

- industrial board washing

- depanelization

- routing

- testing

All of our services are implemented with total ISO 9001:2015 and ISO Medical 13485 quality control and built to IPC 610 Class 2 and 3 specifications.

GIC: Who We Are

Graphics and Industrial Circuits (GIC) provides full-service design, assembly, and materials management to customers seeking long-term contract PCBA manufacturing, including automated surface mount, through-hole/legacy, cabling and harness, and manual box build services. Beyond that, we are a workforce committed to quality and service that is equal to the state-of-the-art equipment that we operate.

How do we do that? We are an employee-owned, Midwest firm that consists of people who embody a strong work ethic and who take pride in ownership of the products we manufacture. Our well-tenured workforce does not consider ourselves simply third-party manufacturers, but rather an essential resource that you can count on to advance your unique finished product and stay competitive.

Industries We Serve

News

-

Meet GIC at the Texas Design-2-Part Show – April 1–2, 2026

If you’re sourcing high-quality electronic manufacturing solutions, we’d love to meet you in person. GIC, Ltd. will be exhibiting at the Texas Design-2-Part (D2P) Trade Show on April 1st and 2nd, 2026 at the Irving Convention Center in Irving, TX. The D2P Show is one of the region’s premier events for engineers, OEMs, and manufacturers

-

GIC, LTD Heads to the Design-2-Part Show in Oaks, PA

GIC, LTD is excited to announce that we’ll be exhibiting at the Design-2-Part Show in Oaks, Pennsylvania, one of the region’s premier manufacturing trade events. You can find us at Booth 111, where we’ll be showcasing our precision manufacturing solutions, advanced PCB assembly capabilities, and engineering expertise. About the Design-2-Part Show The Design-2-Part Show brings

-

How PCB Layout Impacts Thermal Management and Performance

Effective PCB thermal management starts long before production. The way components are arranged, how copper is distributed, and what materials are chosen all determine how well heat is controlled. When heat isn’t managed, circuits can slow down, degrade, or even fail. At GIC, our engineers design every layout to balance performance, reliability, and manufacturability—so our